Welcome to Ganga Metco

Precision in Metal

Power in Manufacturing

Trusted Manufacturer of High-Quality Sheet Metal Products, Custom Enclosures & Powder Coating Solutions Across India.

State-of-the-Art Manufacturing

(Sheet size: 1500 x 2500 mm)

5 CNC Bending Machines

(Up to 3 meters)

45 Power Press Machines

(10–100 tons)

122,000+ products/month

98% on-time delivery

Monthly

Capacity

190.5 Tons of Metal Sheets

State-of-the-Art Manufacturing

Why Ganga Metco?

Quality Commitment

Our mission: “Quality First, Innovative Products, Valuable Service.”

We manufacture sturdy, cost-effective, and dependable sheet metal products, following strict quality standards. At Ganga Metco, quality isn’t an act—it’s a habit.

Customer-Centric Approach

We actively listen, adapt, and deliver. Our clients drive our innovation, and their satisfaction shapes our progress

Design Innovation

Using advanced design tools, we simplify the process of creating customized cabinets, doors, lockers, and enclosures. Our designs are user-friendly, long-lasting, and eco-consious.

Our Products

- Sheet Metal Enclosures & Cabinets

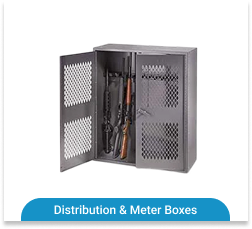

- Distribution & Meter Boxes

- Lighting Products

- Inverter, UPS & Water Purifier Cabinets

- Custom Sheet Metal Components

- Steel Doors, Lockers & Racks

Industries We Serve:-

- Electrical & Electronics

- Power & Energy

- Consumer Appliances

- Retail & Infrastructure

- Industrial Solutions

Materials & Components

We primarily use stainless steel and high-grade sheet metals with a range of precision components such as fasteners, hinges, handles, studs, and gaskets for high-quality fabrication.

Finishing Services

We offer industry-grade powder coating services for lasting protection and aesthetic appeal on all our products.

Trusted by Industry Leaders Like

What Our Clients Say